Wako specializes in manufacturing aircraft parts, jigs,

tools and rolling stock parts

News

-

2024.11.01

We will exhibit at the Aeromart Toulouse 2024. This exhibition is World's largest general aerospace exhibition.

Date ) December 3(Tue)-5 (Thu)

Place) MEETT – Toulouse Exhibition & Convention Centree

For more information, please visit https://aeromart-toulouse.com/ -

2024.10.11

We will exhibit at the Japan International Aerospace Exhibition 2024.

This exhibition is Japan’s largest general aerospace exhibition, together with major Japanese and foreign companies, government agencies, embassy officials, and industry players.

Booth No. W2-009.

Date & Time)Trade Day October 16 (Wed) 12:00-17:00 / October 17 (Thu)-18 (Fri) 10:00-17:00

Trade/Public Day October 19 (Sat) 10:00-17:00

Place)Tokyo Big Sight West Exhibition Hall

For more information, please visit https://www.japanaerospace.jp

-

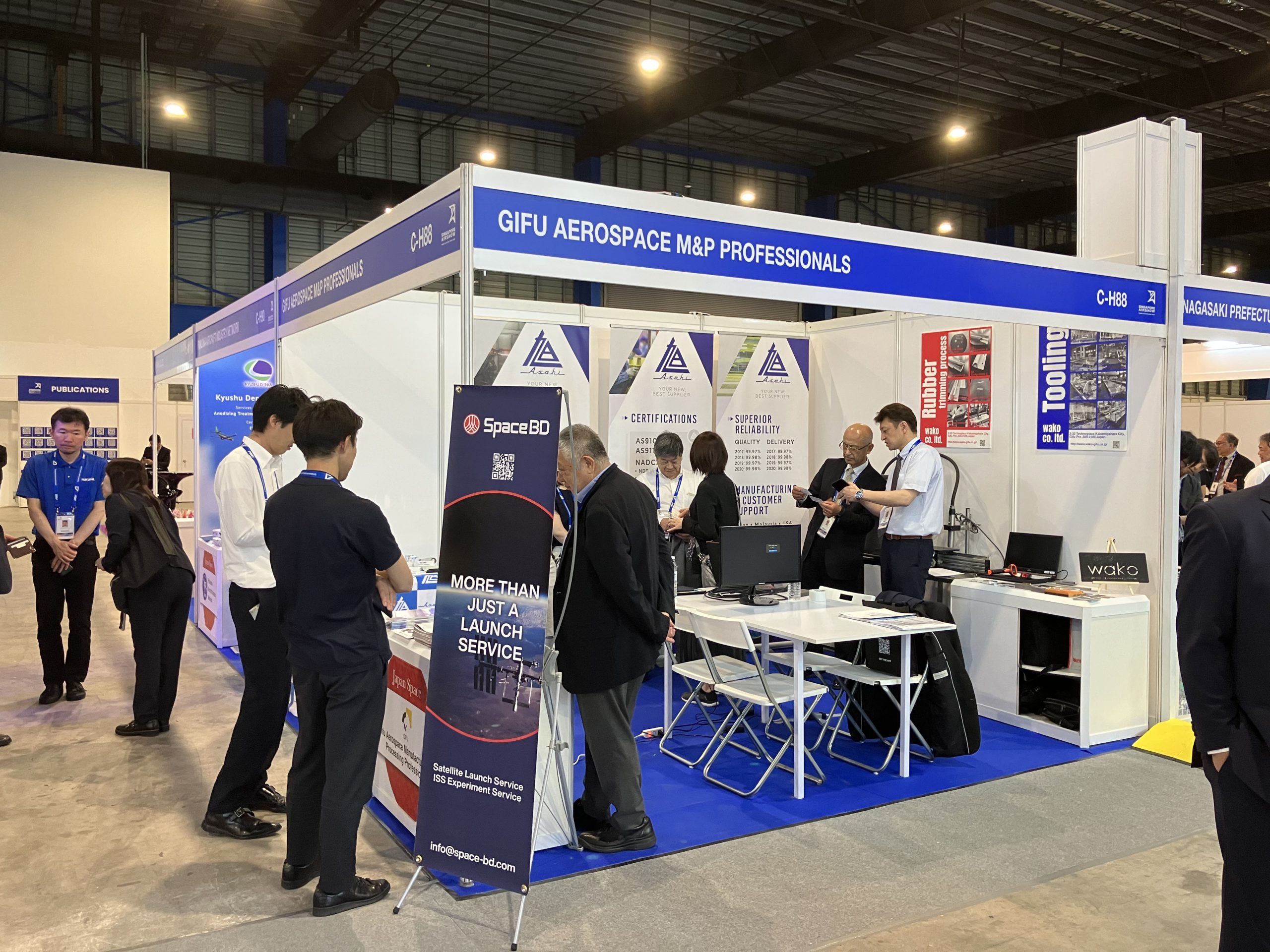

2024.02.20

We exhibited at Singapore Air Show 2024

We exhibited as a cluster of Gifu Prefecture.

We are grateful to all the people involved for making many meaningful business meetings possible.

Products

Facilities

About us

Philosophy

Working for a Better World

Better products and services by improving our:

Technology, Integrity, Reliability.

Message

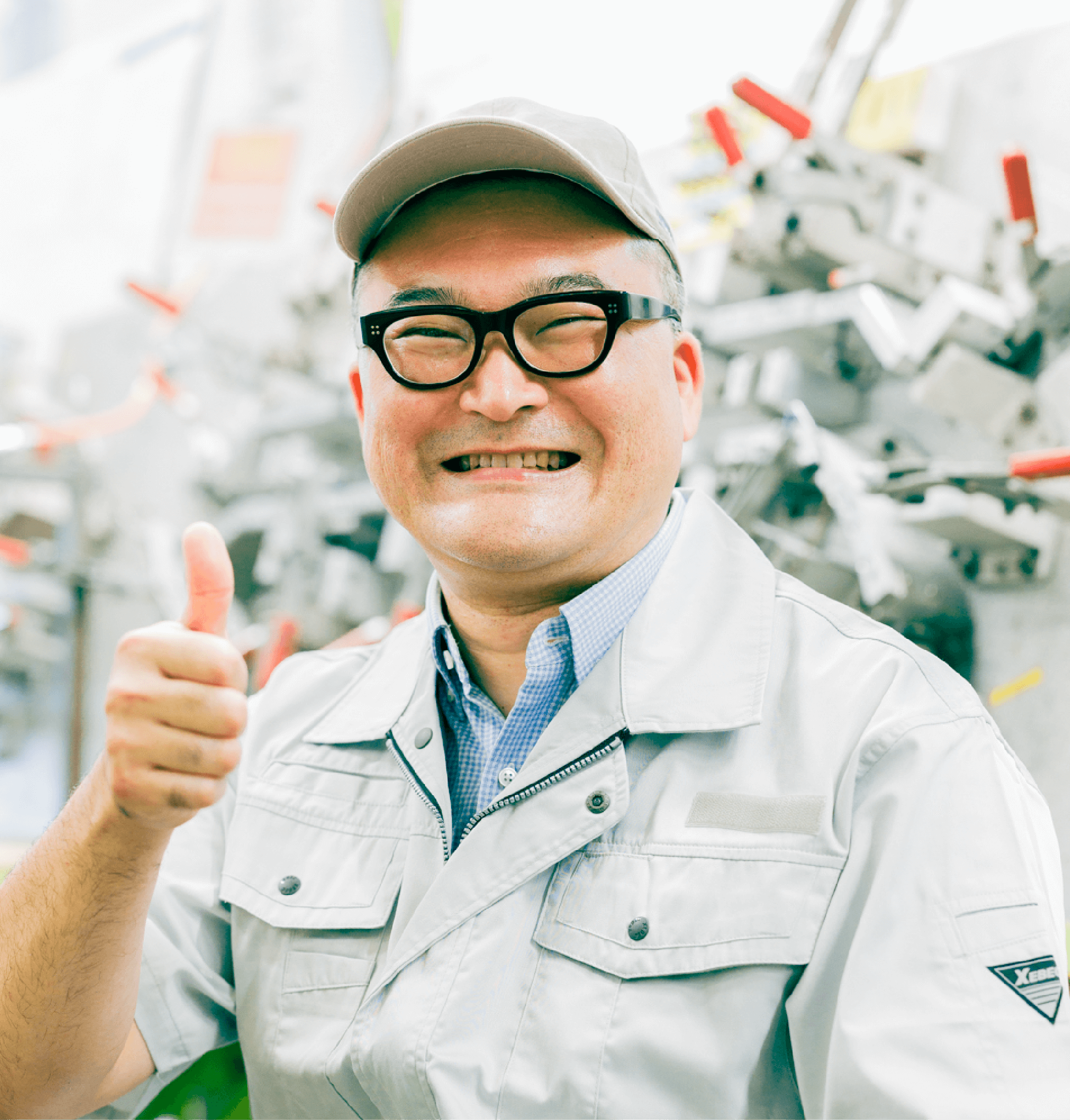

On several occasions in the past, I witnessed that people with strollers or in wheelchairs waiting on the

second floor of a department store, couldn’t find space to fit in the elevator to go downstairs, as it tends

to be full of people coming down from the upper floors. Seeing this, I had an idea for a solution using the

latest technology. One could use AI to monitor a camera placed on each floor to see who is waiting so that it

could control which floor to stop at first. I felt the latest technology, such as image recognition and

artificial intelligence, should be used first for solving the difficulties we face every day, and I also

explored the possibility of proposing such a solution to elevator manufacturers.

However, I came to the conclusion in the end that such an issue can be solved if everyone takes a little bit

of courage and shows generosity to offer their space in the elevator. It is a lot less complicated and free.

We are often captivated by the pace of technological progress and the new conveniences it brings these days.

But sometimes we need to stop and think what we want most and what truly matters in our lives.

I would like our company to focus on working in harmony, followed by technological advancement and company

growth. I also hope our employees find the job they do fulfilling, and that is the basis for our technological

development and company growth.

We are committed to contributing to society as we progress in our business, following the ethos from our

founder,

“世のため人のため―work for betterment of society and humanity”.

Atsunori Hashimoto

Representative Director

Wako Co. Ltd

Company Profile

- Company Name

- Wako Co., Ltd.

- Techno Factory

- 2-33 Techno Plaza, Kakamigahara-City, Gifu Prefecture, Japan, 509-0109

- Sohara Factory

- 3-11 Sohara Koa-cho, Kakamigahara-City, Gifu Prefecture, Japan,504-0814

- TEL

- Techno Factory:+81-58-322-3135 Sohara Factory:+81-58-382-3126

- Representative

- Representative Director Atsunori Hashimoto

- Date of Establishment

- 1972. 12. 18

- Capital

- 10,000thousand yen

- Number of Employees

- 76 (as of July 2024)

- Main Customer

- Kawasaki Heavy Industries, Ltd. / Kawaju Gifu Engineering Co., Ltd.

KGM Co., Ltd. / NIPPI Corporation. / ShinMaywa Industries, Ltd.

Airbus Helicopters Japan Co.,Ltd. / Mitsubishi Heavy Industries, Ltd.

Kawasaki Railcar Manufacturing Co., Ltd. / Japan Transport Engineering Company

NIPPON SHARYO, LTD. / The Kinkisharyo Co.,Ltd. / Narita Mfg., Ltd. - Factory Overview

- Tekuno Factory : Site area 5,086㎡ / Building area 2,204㎡

Sohara Factory : Site area 2,308㎡ / Building area 1,470㎡ - Main Products and Services

- Aircraft sheet metal processing

Aircraft body parts assembly

Jigs and tools for aircraft

Rolling stock metal welding parts

Rolling stock metal plate works - We are certified in the sector of

- JIS Q 9100:2016 (Aerospace industry)

JIS Q 9001:2015 (Rolling stock/Jigs and tools) - We are also qualified for welding.

- JISZ3811 TN-1F、MN-1F

JISZ3841 SN-1F、SA-2F

JISZ3821 TN-F、TN-H

History

- 1972

- The company was established.

- 1973

- Began providing services and parts to Kawasaki Heavy Industries’ Gifu Works.

- 1974

- Became the designated provider to Kawasaki Heavy Industries’ Gifu Works.

- 1975

- Expanded the factory.

- 1979

- Expanded the factory further.

- 1980

- Started to update factory facility incl. NC.

- 1988

- Began providing services and parts to Kawasaki Heavy Industries’ Hyogo Works.

- 2012

- Completed the building of Techno Factory.

Head Quarter office relocated. - 2014

- Certified with JIS Q9100 JIS Q9001.

- 2016

- Participated in Hien (WW II fighter plane) Restoration Project initiated

by Kawasaki Heavy Industries to celebrate their 120th anniversary. - 2017

- Began providing services to Nippon Sharyo Ltd.

- 2023

- Began providing services and parts to Mitsubishi Heavy Industries.

Exhibited at Aero Mart Nagoya 2023. - 2024

- Exhibited at Singapore Air Show.

Started providing services and parts to Airbus Helicopters Japan Co., Ltd.

Exhibited at Japan International Aerospace Exhibition 2024.

Access

Techno Factory

2-33 Techno Plaza, Kakamigahara-City, Gifu Prefecture,

Japan, 509-0109

TEL.+81-58-322-3135

[ Access to Techno Factory ]

15 mins from Gifu Kakamigahara I.C.

10 mins from Seki I.C.

10 mins from JR Sohara Station (Takayama Main Line)

50 mins from JR Gifu Hashima Station (Tokai Shinkansen)

Sohara Factory

3-11 Sohara Koa-cho, Kakamigahara-City, Gifu Prefecture,

Japan,504-0814

TEL.+81-58-382-3126

[ Access to Sohara Factory ]

10 mins from Gifu Kakamigahara I.C.

15 mins from Seki I.C.

45 mins from JR Gifu Hashima Station (Tokai Shinkansen)

10 mins from JR Sohara Station (Takayama Main Line)